Power Transmission

Power transmission systems are essential components in robotics that transfer mechanical energy from motors to various moving parts. Here's an overview of key power transmission mechanisms used in robotics:

1. Key and Keyway

A key is a machine element used to connect a rotating component (such as a gear or pulley) to a shaft. This connection:

Prevents relative rotation between the shaft and the mounted component

Enables efficient torque transmission

May still allow axial movement along the shaft

The complete system consists of:

Key: Usually a rectangular piece of steel that fits into matching slots

Keyway: The slot cut into the shaft

Keyseat: The corresponding slot in the hub of the mounted component

Keyed joint: The complete assembly of these components

Different types of keys include:

Parallel Keys: Square or rectangular keys that run along the shaft length

Woodruff Keys: Semicircular keys inserted into curved slots in the shaft

Taper and Gib-head Keys: Used for heavy, unidirectional, reversing, and vibrating torques

Feather Keys: Square parallel keys with curved ends of fixed radius

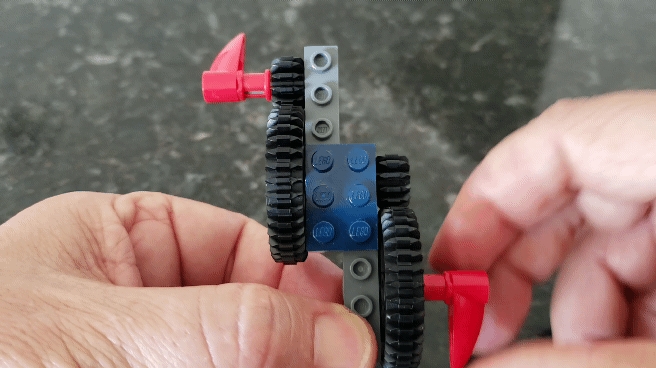

2. Gear Trains

Gear trains transfer rotational motion between shafts using meshed gears. They offer precise control of speed and torque, making them ideal for robotics applications.

Types of gear trains include:

Simple gear train: Basic arrangement with gears on parallel shafts

Compound gear train: Multiple gears on intermediate shafts, allowing for larger velocity ratios

Epicyclic (planetary) gear train: Complex arrangement with a central sun gear, planet gears, and an outer ring gear

Gear trains in robotics enable:

Precise speed control

Torque multiplication

Direction changes

Compact power transmission

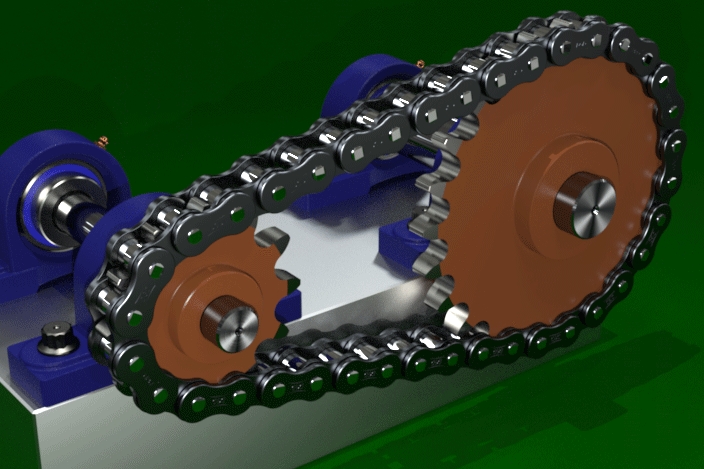

3. Chain and Sprockets

Chain and sprocket systems transfer rotational motion between distant shafts using a toothed wheel (sprocket) and a chain. The sprocket teeth mesh with the chain links to transmit power without slippage.

Key components:

Sprocket: Toothed wheel that engages with the chain

Chain: Series of connected links that transfer power

Applications in robotics include:

Power transmission over longer distances than gears

Situations requiring consistent speed ratios

Robotic arms and manipulators

Mobile robot drive systems

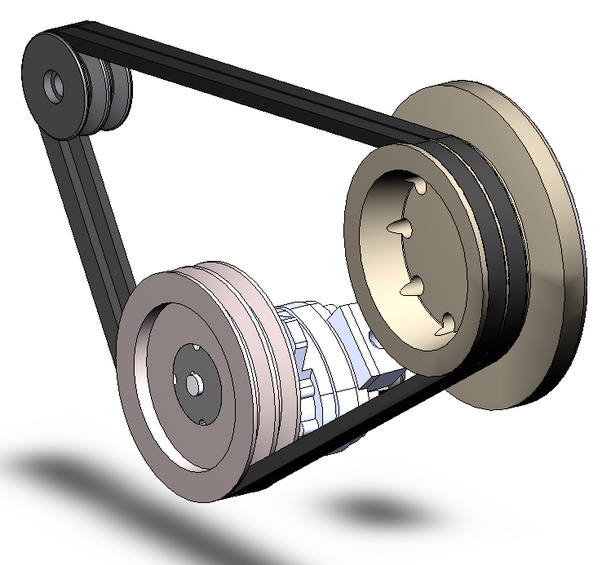

4. Belt Drives

V-Belts

V-belts have a trapezoidal cross-section that fits into matching grooved pulleys. They offer several advantages:

Better grip and traction than flat belts

Higher power transmission efficiency

Increased load-carrying capacity

Reduced noise and vibration

Less slippage under load

V-belts are commonly used in robotics applications requiring moderate power transmission with some flexibility in alignment.

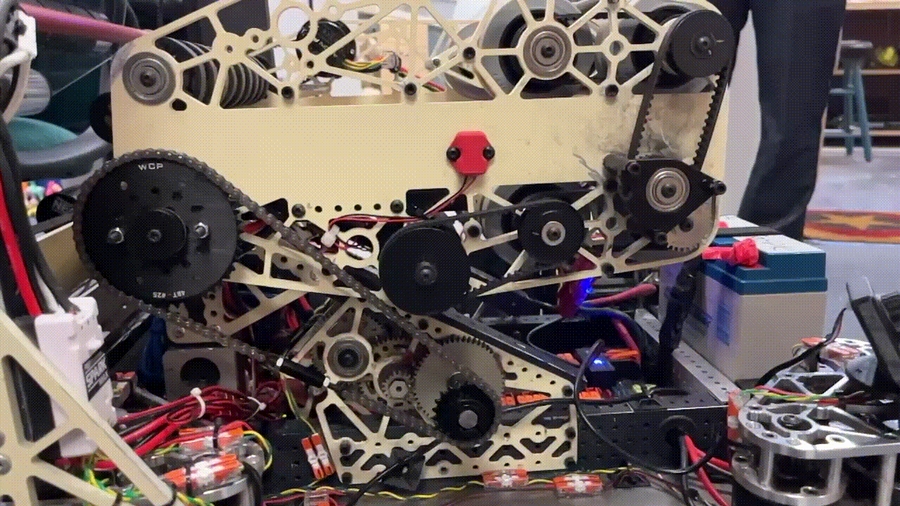

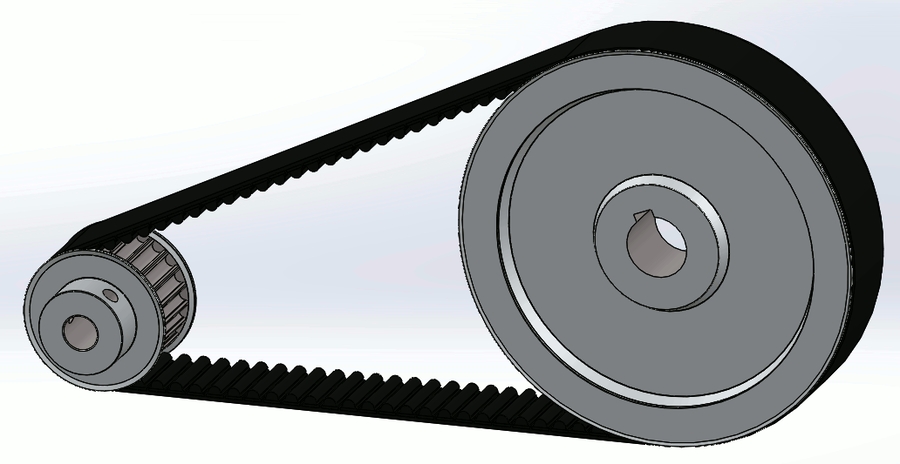

Timing Belts

Timing belts (also called synchronous belts) feature teeth molded onto their inner surface that mesh with grooved pulleys. They combine the flexibility of belt drives with the precision of gear systems.

Advantages of timing belts in robotics:

No slippage, ensuring precise synchronization

Maintenance-free operation (no re-tensioning required)

High efficiency (98-99%)

Quieter operation than chains

Clean operation without lubrication

Each power transmission method has specific advantages and applications in robotics, with the choice depending on factors like required precision, load characteristics, space constraints, and maintenance considerations.

Last updated