Common Mechanisms

Flywheel Shooter

Construction

Two counter-rotating wheels (often with compliant covers) mounted on motor shafts, spaced to pinch a round projectile.

Motors may include encoders for closed-loop speed control.

Use Cases

Rapid-fire launch of small, spherical game pieces (e.g., Power Cells, foam balls).

Advantages

Continuous, high-rate firing-no reload cycle time needed.

Velocity (and thus range) can be tuned on the fly by adjusting wheel speed.

Disadvantages

Only handles round objects reliably-non-spherical items slip or jam. 2

Motor speed (and shot consistency) falls off as battery voltage drops unless actively regulated by encoders. 2

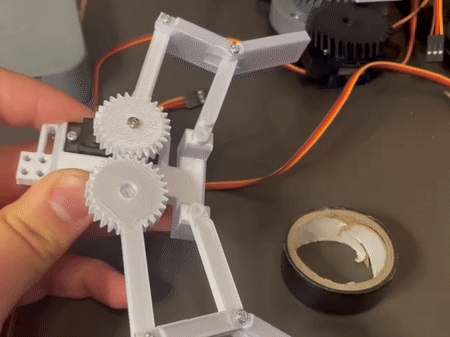

Striker (“Impact”) Shooter

Construction

Rigid striker arm or plate driven by a geared motor or spring, which impacts the projectile to launch it.

Includes a pull-back mechanism (e.g., a torque motor with gear train) to reset the striker.

Use Cases

Launching flat or irregular objects (pucks, square blocks) that cannot be gripped by wheels.

Advantages

Compatible with a wide variety of shapes and sizes. 2

Range adjustable by tuning spring tension or motor torque. 2

Disadvantages

Energy loss to friction when the object slides against a surface reduces distance. 2

High impact loads cause wear on linkages and mounting hardware. 2

Reset mechanism adds cycle time and mechanical complexity. 2

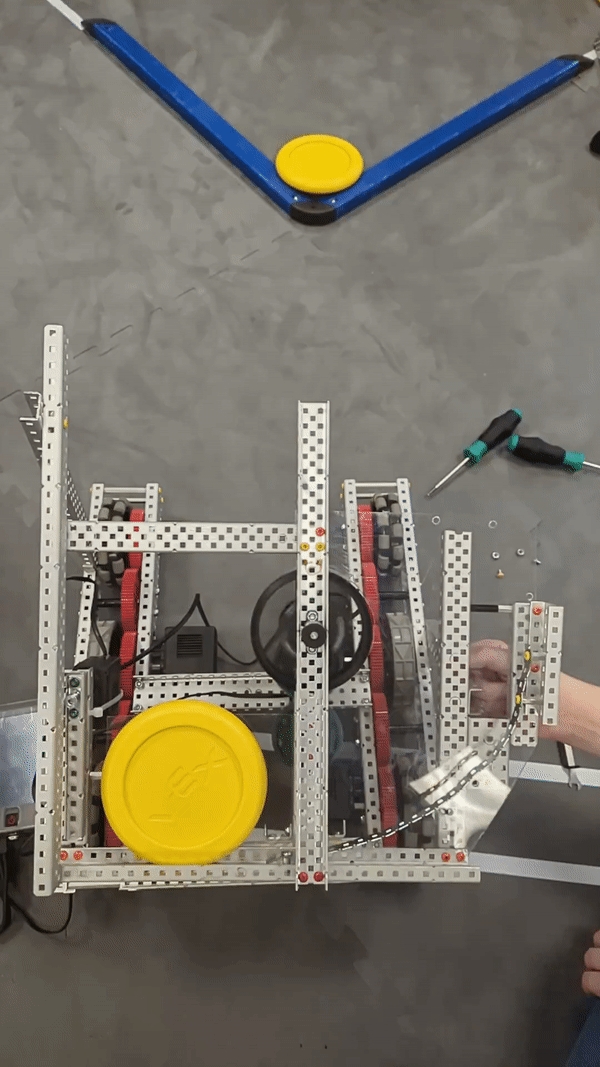

Catapult/Popper Shooter

Construction

Elastic element (rubber band or spring) attached to an arm linkage, latched by a servo or pin.

Release mechanism discharges stored energy to fling the projectile.

Use Cases

Single-shot loops at moderate rate for uniform, repeatable distance (e.g., tennis-ball poppers, small foam ring launchers).

Advantages

Very consistent shot energy and accuracy thanks to fixed spring tension. 6

Simple control: prime once, trigger, then re-prime.

Disadvantages

Fixed launch distance unless spring tension is manually adjusted between shots. 6

Mechanical linkage must absorb high forces, leading to potential fatigue and breakage.

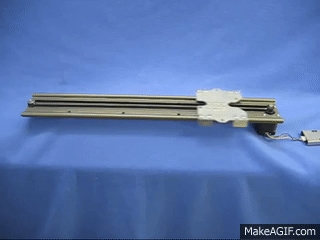

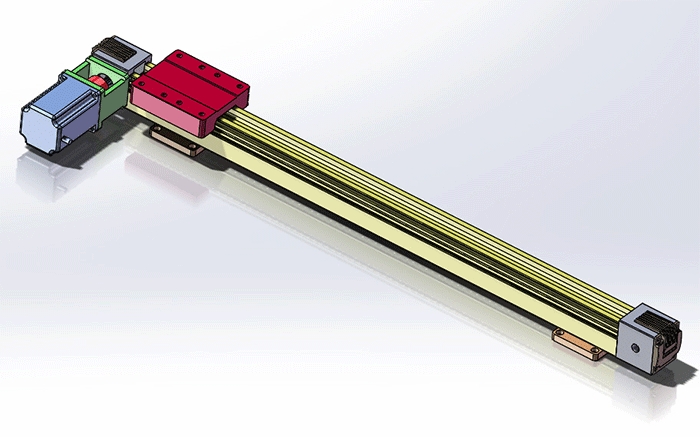

Linear Motion Guides

Construction: Aluminum extrusion or steel rail profiles with rolling or plain bearings (linear slides, drawer slides, profile rails). 2 Use Cases

Robot lifts, elevators, extendable arms, precise slide mechanisms Advantages

Recirculating bearings: smooth, low friction under load

Profile rails: tight tolerances, long life Disadvantages

Adds weight and cost

Requires precise alignment and mounting

Arms & Elevators

Construction: Pivoting bars or telescoping frames driven by motors, winches, or actuators; may include cascade or continuous-loop rigging. 2 Use Cases

Scoring at various heights, reaching over obstacles

Gripper positioning and manipulator extension Advantages

Pivot arms: simple kinematics, compact stowage

Telescopes: extendable range, rigid at full height Disadvantages

Pivot: limited vertical reach without long links

Telescopes: mechanical complexity, potential binding

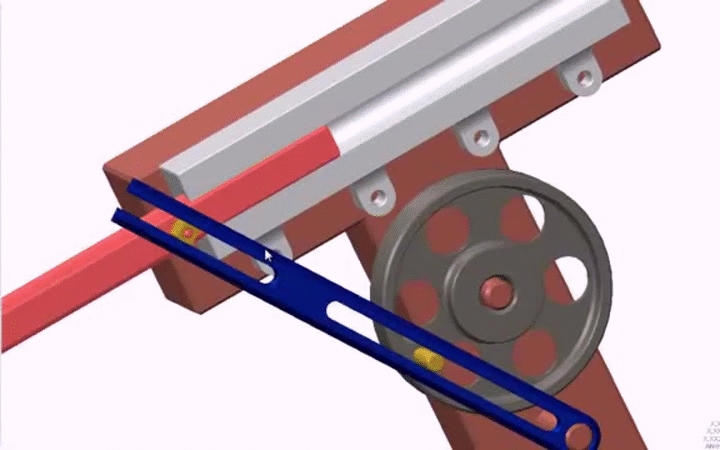

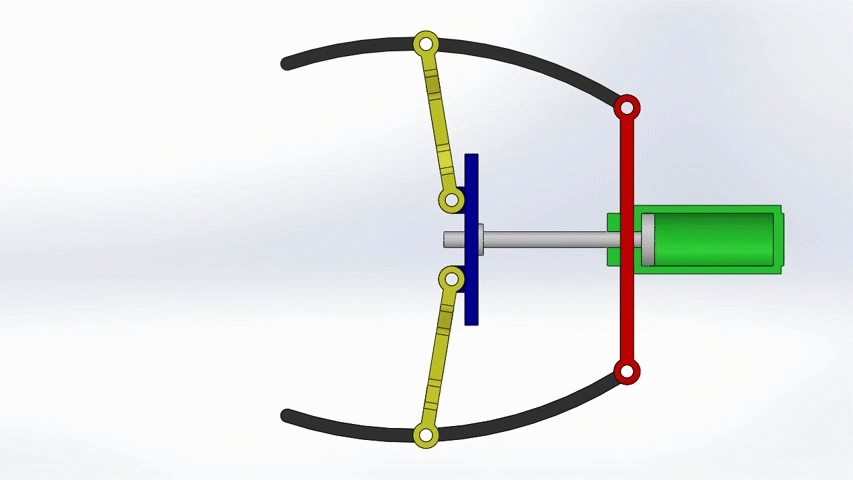

Linkages

Construction: Rigid links connected by revolute (pin) joints, forming Four-Bar, Parallel (pantograph), Scissor, Corner, or Cross linkages. 2 Use Cases

Converting rotary motor motion into complex planar or vertical motion

Lifts, level platforms, bilateral extension Advantages

Four-Bar: predictable motion path, adjustable leverage

Scissor: large vertical extension in compact footprint

Pantograph: maintain parallel output motion Disadvantages

Multiple joints: cumulative backlash and wear

Scissor: linkage binding without precise fabrication

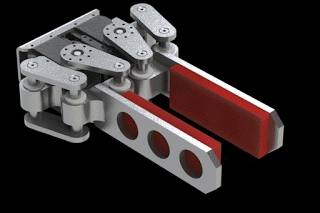

Passive Intakes & Claws

Construction: Fixed mounting plates with compliant materials (rubber bands, foam), passive rollers or fingers. 2 Use Cases

Gripping variable-shape game pieces without active actuation

Centering objects against a backplate for further processing Advantages

Low complexity, minimal actuators required

Gentle on game pieces, self-centering behavior Disadvantages

Limited gripping force, shape dependence

No active release control

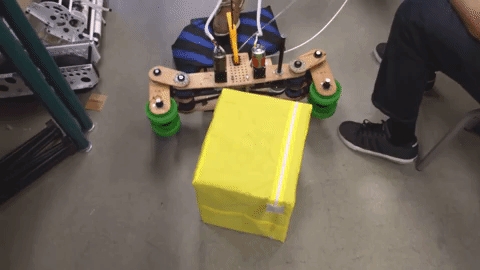

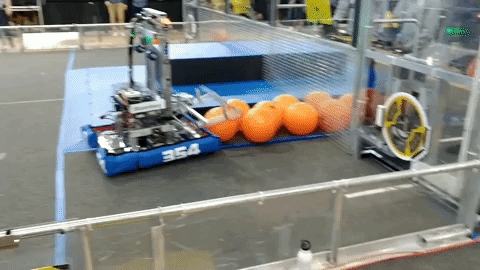

Active Intakes

Construction: Powered rollers, wheels, or pneumatic fingers mounted on pivoting arms or frames. 2 Use Cases

High-speed collection of balls, cubes, rings, or custom game pieces

Feeding objects into indexers or shooters Advantages

Controlled grasping and ejection, high throughput

Adjustable speed and torque for different materials Disadvantages

Additional motors or pneumatics add weight and draw current

Complex timing and synchronization with downstream subsystems

Transfers & Indexers

Construction: Belt or roller conveyors, pneumatic gates, channel guides, and staging shelves. 2 Use Cases

Sequencing multiple game pieces, buffering under shooters or scoring mechanisms

Automated stacking or batch delivery Advantages

Precise object positioning, continuous feeding

Scalable to multiple game-piece types Disadvantages

Added length and mass on the robot

Requires control logic to avoid jams

Dead (Idle) Wheels

Construction: Free-spinning omni or traction wheels mounted on bearings, used as load-bearing supports. 2 Use Cases

Reducing friction on non-driving corners

Stabilizing mechanisms or gantry plates Advantages

Simple, passive way to carry loads without consuming motor power

Minimal wear on drive motors Disadvantages

Adds drag if misaligned

Does not contribute to motion

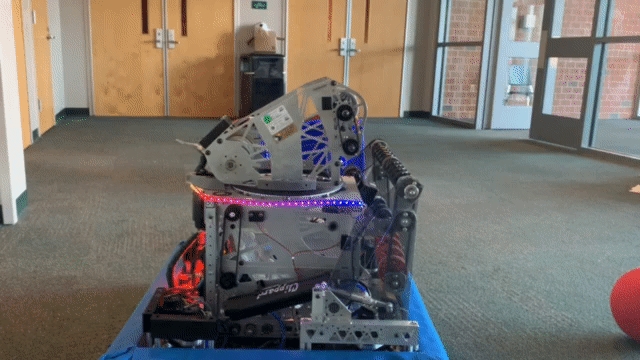

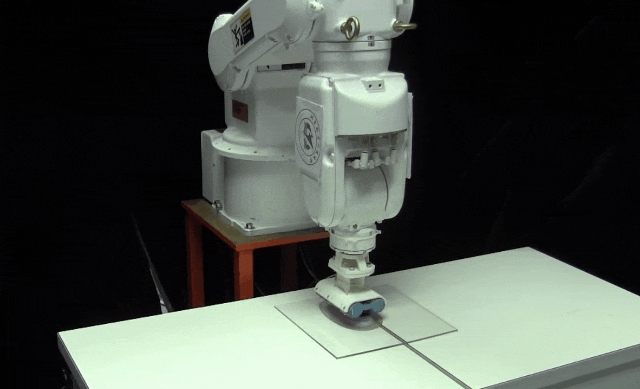

Turrets

Construction: Rotating subplate on thrust bearings or lazy-Susans, driven by motors or servos. 2 Use Cases

Aiming shooters or sensors independently of chassis orientation

Multi-directional intake or scoring without turning the robot Advantages

Decouples turret and chassis control, rapid targeting

Enables continuous rotation and precise angular positioning Disadvantages

Complex wiring management (slip rings or cable chains)

Increased mass and higher center of gravity

Forklift Mechanisms

Above shown Screw and Belt Driven Linear Guides can also be used

Construction

A rigid rectangular frame built from metal tubing or plates supports four drive motors with reduction gearing and a single H-bridge controller for traction and steering6.

A vertical lift assembly uses profile rails or linear slide tracks on each side to guide motion, with a rack-and-pinion driven by a DC motor to raise and lower forks or a carriage2.

Ultrasonic distance sensors mounted near the base detect shelf or object positions and trigger lift actions, all wired through a microcontroller (e.g., Arduino Uno) and soldered onto a breadboard for flexible I/O expansion2.

Use Cases

Warehouse and warehouse-style competition challenges requiring precise fork positioning under pallets or blocks.

Educational projects demonstrating pick-and-place automation, obstacle avoidance, and sensor integration.

Advantages

High load capacity and stable vertical motion when properly counterbalanced.

Precise height control via gear reduction and encoder feedback.

Modular design allows easy adjustment of fork width and lift height.

Disadvantages

Heavy lift assemblies can unbalance the drive base, requiring careful weight distribution or repositioning of components2.

Increased mechanical complexity and part count raise build time and maintenance.

Rack-and-pinion systems can bind if rails are misaligned or not lubricated.

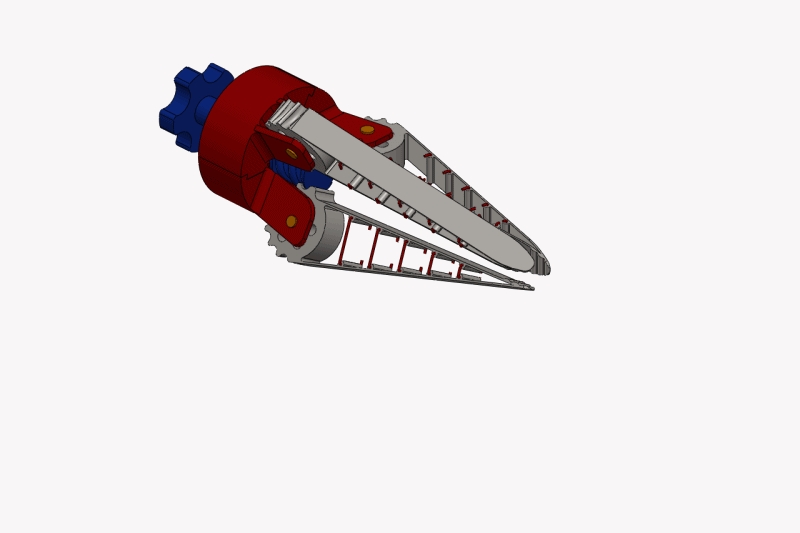

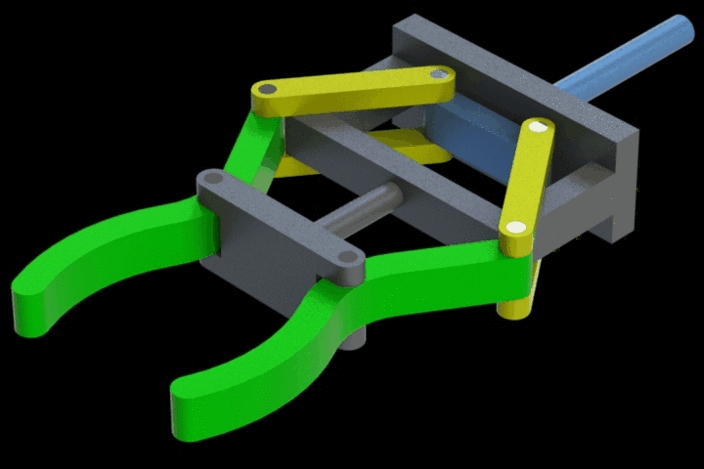

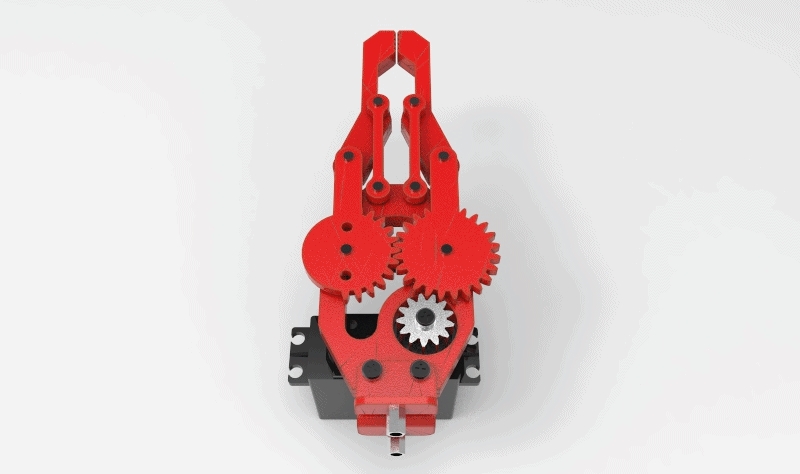

Robotic Grippers

Mechanical Grippers

Construction: Two or more rigid fingers actuated by servos, motors, or linkages; often include compliant pads for better friction3.

Use Cases: General-purpose part handling, from small rigid game pieces to irregular objects in warehouses.

Advantages: High grip force, adaptability to varied geometries, straightforward control.

Disadvantages: Complex designs for large workpieces, increased weight, limited softness for fragile items3.

Vacuum Grippers

Construction: Suction cups linked to a vacuum pump or venturi generator, often with integrated pressure sensors4.

Use Cases: Handling flat, smooth panels, sheet goods, glass, and light game elements.

Advantages: Simple design, fast pick-and-place cycles, low profile for tight spaces.

Disadvantages: Only works on non-porous surfaces; rubber cups wear and require frequent replacement3.

Magnetic Grippers

Use Cases: Lifting ferrous parts, sheet metal handling, assembly tasks with metallic game pieces.

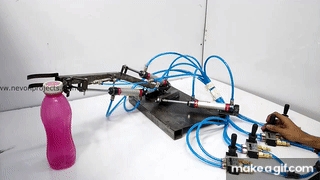

Pneumatic Grippers

Construction: Parallel or angular jaw fingers driven by air cylinders, with flow control valves for speed and force tuning4.

Use Cases: High-speed pick-and-place, automated packaging, fluid-tight sealing in assembly.

Advantages: High force-to-weight ratio, fast actuation, built-in compliance.

Disadvantages: Requires compressed air infrastructure, noisy operation, potential air leaks.

Servo-Electric Grippers

Construction: Brushless or stepper motors with gearboxes driving finger linkages, often with integrated position and force sensors4.

Use Cases: Precision handling in electronics assembly, variable-force tasks in competition robots.

Advantages: Precise position and force control, easy integration with digital controllers, low maintenance.

Disadvantages: Higher cost, more complex control algorithms, potential heat generation in continuous use.

Last updated